We are proud to be a leading manufacturer and supplier of high-quality underground water storage solutions. With over 15 years of hands-on experience in the industry, our expertise in underground water tank design ensures that you receive reliable, efficient, and safe water storage systems tailored to your specific needs. This comprehensive guide outlines essential design considerations to help you create an effective underground water storage tank, all backed by our commitment to excellence and customer satisfaction.

Understanding Underground Water Tank Design

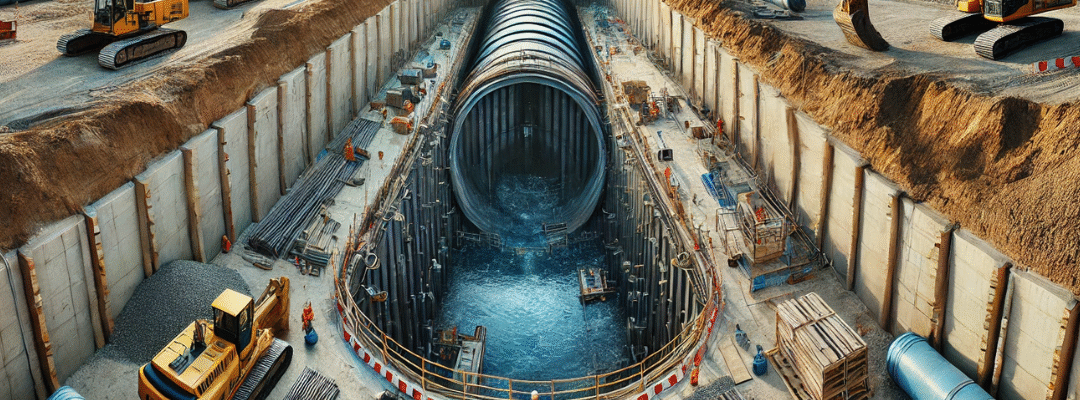

The design of an underground water tank is critical for ensuring longevity, safety, and efficiency. A well-thought-out design can prevent leaks, maintain water quality, and withstand environmental pressures, ultimately providing peace of mind for users. Our team of certified engineers employs industry best practices and adheres to the latest Australian Standards, ensuring that every tank we design meets rigorous safety and performance benchmarks

1.Define Purpose & Estimate Capacity

Usage-Based Sizing

Understanding the intended use of your underground water tank is crucial. Whether for drinking water, fire suppression, greywater reuse, or irrigation, identifying the purpose will help determine daily demand and calculate the required storage capacity. For instance, a residential tank for irrigation may need to hold a different volume compared to a commercial tank designed for fire safety. Our team can assist you in accurately estimating your needs based on real-world applications, drawing from our extensive experience in various sectors.

Storage Duration

Consider the backup needs based on seasonal rainfall trends. In arid regions, tanks may need to hold several weeks’ worth of water to ensure a consistent supply, while urban areas may require different strategies. Proactive planning can significantly reduce water shortages during dry spells, ensuring your system remains functional when you need it most.

2.Assess Site & Location Factors

Soil Profile

Conducting a thorough geotechnical analysis to evaluate soil type, groundwater table, and load-bearing capacity is essential. For example, clay-heavy or loose soils may require additional stabilization to support the tank effectively. We recommend engaging with local geotechnical experts to ensure accurate assessments and optimal design, as we have done in numerous successful projects across diverse terrains.

Drainage Considerations

Select a location away from flood-prone areas and ensure proper perimeter drainage to mitigate hydrostatic pressure during storms, which can compromise tank integrity. Effective drainage solutions are vital for long-term tank performance and can prevent costly repairs.

Access & Obstructions

Ensure that the tank’s placement does not interfere with building foundations, tree roots, or utility lines. This consideration facilitates easy access for maintenance and inspections, which are crucial for the tank’s longevity.

3.Select the Right Material for Your Tank

Choosing the appropriate material for your underground water tank is vital for durability and functionality:

- Reinforced Concrete: Ideal for large-capacity or high-load scenarios, such as installations beneath driveways. Our concrete tanks meet Australian Standards for structural integrity and have been successfully used in numerous commercial projects, including municipal water supply systems.

- HDPE (High-Density Polyethylene): Lightweight and corrosion-resistant, making it suitable for smaller residential applications. Our HDPE tanks are UV-stabilized for longevity and have been tested in various environmental conditions, ensuring they stand the test of time.

- Stainless or Galvanized Steel: Durable but requires anti-corrosion treatment, best for industrial or potable water storage. We use high-quality coatings to enhance durability, ensuring compliance with industry standards.

- Fiberglass (FRP): Non-corrosive and strong, perfect for chemically treated or non-potable water systems. Our fiberglass tanks are designed to withstand harsh chemical environments, backed by customer testimonials praising their reliability.

4.Waterproofing & Leak Prevention Strategies

Implement a multi-layer protection strategy by combining external coatings (e.g., bitumen or epoxy) with internal liners (PVC or rubber) to ensure redundancy against leaks. Proper management of seams and joints is essential, using waterproof sealants like polyurethane or butyl rubber. Our tanks undergo rigorous testing to ensure leak-proof performance, and we provide a warranty to back our claims, reflecting our confidence in our products.

5.Structural & Load Considerations

Shape Optimization

Cylindrical tanks provide better stress distribution in high-pressure environments, while rectangular designs may be more suitable for tight urban spaces. Our design team can help you choose the optimal shape based on site-specific conditions and practical use cases, ensuring maximum efficiency and safety.

Traffic Load Design

If your tank is installed beneath driveways or parking lots, it must be engineered to withstand both dynamic and static vehicle loads to ensure safety and durability. We adhere to the latest engineering standards to guarantee structural integrity, having successfully completed numerous projects in high-traffic areas.

Backfill Engineering

Utilize compacted layers and follow backfill specifications recommended by the tank manufacturer to ensure stability and prevent shifting. Our installation teams are trained in best practices for backfilling to ensure optimal performance, reducing the risk of future issues.

6.Maintenance Access & Safety Features

Incorporate manholes and inspection ports with corrosion-resistant covers. Ensure that built-in ladders or step-irons are available for safe entry. Proper air vents are necessary to prevent vacuum pressure and allow gas dissipation. Our designs prioritize user safety and ease of maintenance, reflecting our commitment to quality.

7.Ventilation & Animal Intrusion Control

Install screened vents to prevent insects, rodents, or reptiles from entering the tank. Use lockable, gasketed access hatches to maintain water hygiene and deter tampering. Our systems are designed with these considerations in mind to ensure water quality, backed by industry best practices.

8.Foundation & Floatation Control

A stable bedding layer, typically 100–150mm thick sand or gravel, is essential for uniform support and drainage. In high water table areas, consider anti-buoyancy systems such as ground anchors or concrete tie-downs. Our engineers can provide tailored solutions for challenging site conditions, ensuring peace of mind for our clients.

9.Ensure Water Quality & Hygiene

Utilize NSF or AS/NZS certified food-grade materials for potable water. Incorporate filtration systems, including pre-tank filters and post-tank treatments like UV or activated carbon, depending on the intended use. Our commitment to quality ensures that your water remains safe and clean, supported by our extensive experience in the field.

10.Temperature Control Measures

For tanks storing potable water in extreme temperature regions, consider thermal insulation. Installing tanks deeper (e.g., >1.2 meters) can help regulate temperature naturally, reducing the risk of algae growth. Our designs incorporate temperature control features to enhance water quality, reflecting our dedication to innovation.

11.Hydrostatic Pressure & Buoyancy Management

Design must account for simultaneous water pressure inside and surrounding groundwater pressure outside the tank. Reinforced walls and bases are necessary for tanks in flood-prone zones to prevent structural failure. Our engineering team specializes in designing tanks that withstand these pressures, ensuring long-term reliability.

12.Piping & Hydraulic Design Considerations

Ensure flow efficiency by placing pipes to prevent sediment buildup and allow full tank emptying. Include anti-siphon and backflow devices for potable systems to prevent contamination and ensure safe water delivery. Our hydraulic designs are optimized for performance and safety, demonstrated by our successful installations.

13.Compliance with Local Regulations

Adhere to local building codes, water authority standards, and EPA/WHO guidelines for water quality and structural safety. Conduct an environmental review to consider groundwater protection and stormwater impact, ensuring your design is sustainable. We stay updated on regulatory changes to ensure compliance, giving you confidence in our expertise.

14.Design for Long-Term Durability

Aim for a lifespan of at least 30–50 years with minimal intervention by using durable materials and protective coatings. Implement corrosion control measures, especially in saline or acidic soil conditions, to extend the tank’s life. Our tanks are built to last, backed by warranties that reflect our confidence in their durability.