We are proud to be a leading manufacturer and supplier of innovative water storage solutions, with over 15 years of hands-on experience in the industry. Our deep understanding of the crucial role that water tanks play in various applications—ranging from residential homes to large-scale industrial facilities—enables us to provide tailored solutions that meet diverse needs. Water tanks are essential for storing potable water, rainwater, firewater, and industrial liquids, and the construction method you choose can significantly impact performance, durability, and cost-effectiveness. This comprehensive guide offers an in-depth overview of common water tank construction techniques, detailing their processes, advantages, and disadvantages.

1.Reinforced Concrete Tanks

Overview

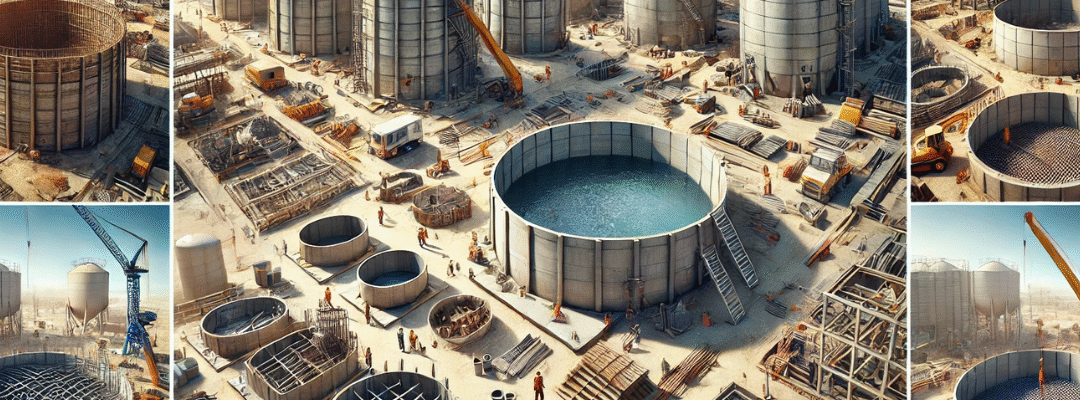

Reinforced Concrete Tanks (RCC) are constructed using cast-in-situ or precast panels, making them ideal for large-scale or underground storage. Their robust design is particularly effective in areas with high water tables or seismic activity, ensuring reliability and safety.

Construction Process

- Cast-in-situ: On-site formwork and reinforcement are meticulously set up, followed by pouring and curing high-strength concrete, ensuring structural integrity.

- Precast: Panels are manufactured off-site in controlled environments and assembled on location, utilizing advanced waterproofing techniques for enhanced durability.

Advantages

- Durability: RCC tanks are renowned for their long-lasting strength and resistance to environmental factors, making them a preferred choice for critical applications.

- Customization: They can be tailored to specific shapes and capacities, accommodating high-volume storage needs.

Disadvantages

- Labor-Intensive: Requires significant on-site labor, which can affect project timelines and costs.

- Curing Needs: Effective curing and waterproofing are critical, necessitating skilled labor to ensure optimal performance.

2.Steel Water Tanks

Overview

Steel Water Tanks are constructed from high-quality steel sheets, either welded or bolted, providing a robust solution for various storage needs. Their versatility makes them suitable for both temporary and permanent installations.

Construction Process

- Welded: Steel plates are expertly joined through welding and coated with corrosion-resistant materials to enhance longevity.

- Bolted: Prefabricated plates are connected with bolts and sealed with high-performance gaskets, allowing for quick assembly and disassembly.

Advantages

- Quick Installation: Steel tanks can be erected rapidly, minimizing downtime and allowing for immediate use.

- Relocatable: Bolted designs facilitate easy relocation, making them ideal for temporary projects or changing needs.

Disadvantages

- Corrosion Risk: Without proper coatings, steel tanks are susceptible to rust, necessitating regular inspections and maintenance.

- Maintenance: Ongoing maintenance is essential for longevity, particularly in harsh environments.

3.Fiberglass Reinforced Plastic (FRP) Tanks

Overview

FRP Tanks are constructed from layers of fiberglass and resin, offering excellent chemical and corrosion resistance, making them particularly useful in chemical processing industries.

Construction Process

These tanks are pre-molded in factories, arriving on-site ready for installation, which streamlines the deployment process.

Advantages

- Lightweight: Simplifies handling and installation, ideal for sites with limited access or challenging terrain.

- Low Maintenance: Requires minimal upkeep, making them a cost-effective choice over time.

Disadvantages

- Size Limitations: Typically limited to small and medium sizes, which may not meet the needs of larger operations.

- Temperature Restrictions: Not recommended for very hot liquids, as extreme temperatures can affect structural integrity.

4.Plastic (Polyethylene) Tanks

Overview

Plastic Tanks are created using rotational molding, resulting in seamless construction that is effective for rainwater harvesting systems and other applications.

Construction Process

Granules are melted and molded into one-piece tanks in factory settings, ensuring a consistent and reliable product.

Advantages

- Cost-Effective: Affordable and lightweight, making them accessible for various budgets and applications.

- Leak Prevention: Seamless design significantly reduces the risk of leaks, ensuring safe storage.

Disadvantages

- Capacity Limitations: Not ideal for large volumes, which may limit their applicability in larger systems.

- UV Degradation: Can degrade with prolonged sun exposure unless treated with UV-resistant coatings.

5.Masonry Tanks

Overview

Masonry Tanks are constructed with bricks, blocks, or stone, sealed with plaster or cement. They offer aesthetic appeal and can blend seamlessly with natural surroundings.

Construction Process

Constructed manually by skilled artisans, these tanks are coated internally to ensure water-tightness and structural integrity.

Advantages

- Cost-Effective: Generally low-cost and labor-friendly, making them an attractive option for budget-conscious projects.

- Local Materials: Can utilize locally sourced materials, reducing transportation costs and supporting local economies.

Disadvantages

- Leakage Risk: Higher risk of leakage due to construction methods that may not provide the same level of sealing as modern materials.

- Structural Limitations: Lower strength compared to other materials, which may affect long-term durability.

Prestressed Concrete Tanks

Overview

Prestressed Concrete Tanks are reinforced with tensioned cables, enhancing their strength and durability for high-demand applications, such as municipal water supply.

Construction Process

Tensioned steel is embedded in concrete, which is then cast and cured, creating a robust structure capable of withstanding extreme conditions.

Advantages

- Crack Resistance: Excellent resistance to cracks and deformation, ensuring long-term reliability.

- Load Capacity: Suitable for extreme loads and conditions, making them ideal for critical infrastructure.

Disadvantages

- High Initial Cost: More expensive to construct due to the complexity of the materials and methods used.

- Skilled Labor Required: Requires specialized teams for installation, which can impact project timelines.

7.Baffle Tanks

Overview

Baffle Tanks feature internal partitions designed to control water movement, making them ideal for wastewater treatment and stormwater management applications.

Construction Process

Typically made of plastic or steel, these tanks are designed with built-in baffles that enhance their functionality.

Advantages

- Stability: Reduces water sloshing during transport, enhancing safety and efficiency.

- Ease of Deployment: Simple and quick to set up, allowing for rapid implementation in urgent situations.

Disadvantages

- Volume Limitations: Less usable volume due to baffles, which may limit storage capacity.

- Not for Large Storage: Best suited for niche applications rather than large-scale storage needs.

8.Buried or Earth-Bermed Tanks

Overview

Buried Tanks are constructed below ground, effectively preserving landscape aesthetics while providing secure water storage.

Construction Process

Involves excavation, tank installation, and backfilling, which requires careful planning and execution.

Advantages

- Aesthetic Appeal: Hidden from view, preserving the landscape and reducing visual impact.

- Natural Insulation: Provides insulation from temperature fluctuations, enhancing water quality.

Disadvantages

- Excavation Costs: Can be costly due to excavation requirements and soil stabilization measures.

- Maintenance Access: Difficult to access for maintenance, which may complicate repairs.

9.Hybrid (Composite) Tanks

Overview

Hybrid Tanks combine materials like steel and concrete for optimized performance, leveraging the strengths of both materials.

Construction Process

Utilizes multi-material construction to create a tank that meets specific performance criteria, making it suitable for diverse applications.

Advantages

- Performance: Combines advantages of various materials, offering enhanced durability and functionality.

- Customization: Tailored to meet specific needs, ensuring optimal performance in unique environments.

Disadvantages

- Design Complexity: Requires specialized design expertise to ensure compatibility and performance.

- Repair Challenges: May complicate repair or expansion efforts due to the variety of materials used.

10.Underground RCC Tanks

Overview

Underground RCC Tanks are designed for safe, long-term water storage, suitable for sensitive applications such as potable water supply.

Construction Process

Involves excavation, reinforcement, concrete casting, and waterproofing, requiring precise engineering to ensure effectiveness.

Advantages

- Security: Durable and secure for sensitive applications, providing peace of mind for critical water storage.

- Space Saving: Frees up surface space for other uses, enhancing land utilization.

Disadvantages

- Waterproofing Precision: Requires high-precision waterproofing to prevent leaks and ensure safety.

- Costly Excavation: Excavation can significantly increase costs, necessitating careful budget planning.

11.Modular Tanks

Overview

Modular Tanks consist of interlocking prefabricated panels, offering flexibility and efficiency in rapidly changing environments.

Construction Process

Components are shipped and assembled on-site for quick deployment, making them ideal for temporary or emergency situations.

Advantages

- Rapid Installation: Quick to set up and take down, allowing for immediate water storage solutions.

- Scalability: Easily scalable and relocatable, adapting to changing needs without significant investment.

Disadvantages

- Cost Considerations: Higher costs for larger capacities may deter some projects.

- Inspection Needs: Joints may require regular inspection to ensure structural integrity and performance.