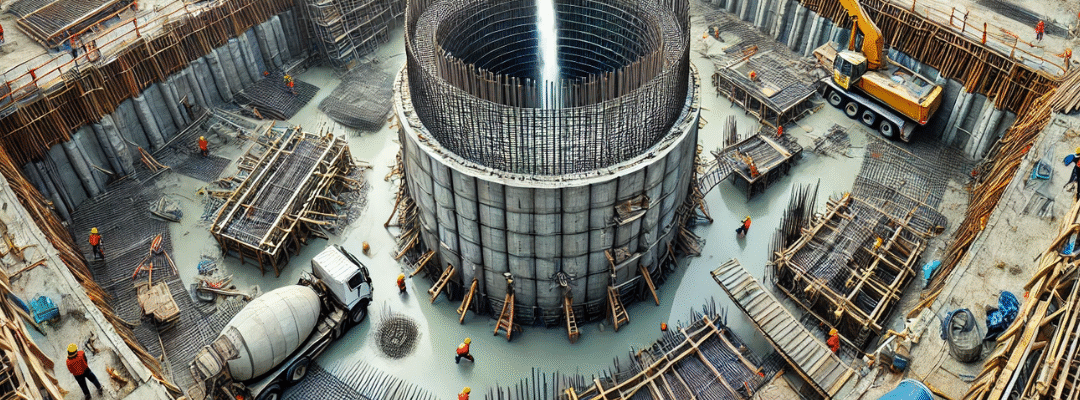

How to Reinforce RCC Underground Water Tanks for Durability and Leak Resistance

Reinforced Cement Concrete (RCC) underground water tanks are widely used for storing potable and non-potable water, especially in residential and industrial settings. However, without proper reinforcement, these tanks are prone to structural stress, cracking, and water leakage. Below is a comprehensive guide on how to reinforce RCC underground water tanks to ensure long-lasting performance and structural integrity.

1.Integrating Structural Rebars for Load-Bearing Strength

Concrete alone cannot handle tensile stress. Embedding high-tensile steel rebars provides the tank with the ability to resist both internal water pressure and external soil load.

Key Steps:

Install a rebar mesh grid in the floor, walls, and ceiling of the tank.

For large-capacity tanks, use dual layers of rebar on both inner and outer faces.

Ensure a concrete cover of at least 25–50 mm to prevent corrosion from groundwater exposure.

Why it Matters: Steel reinforcement counteracts tensile forces and keeps the structure stable under variable loading conditions.

2.Designing for Hoop Stress and Vertical Loads

Reinforcement must be placed in two directions:

Horizontal reinforcement (circumferential rings) helps resist hoop stress, particularly important in cylindrical tanks.

Vertical steel bars distribute vertical loads and strengthen vulnerable areas like corners and junctions.

Pro Tip: Add extra steel at slab-to-wall junctions where stress tends to concentrate.

3.Shear Reinforcement Using Stirrups

To prevent diagonal shear failure, especially at wall bases and joints, incorporate shear reinforcement in the form of:

Closed stirrups or ties spaced evenly along wall sections.

Concentrated stirrups at high-stress transition zones such as wall-footing intersections.

This ensures tank stability during ground movement or internal pressure shifts.

4.Enhancing Waterproofing with Admixtures

Even the best concrete mix is porous over time. Introducing waterproofing additives makes the tank more resilient to moisture infiltration.

Options Include:

Crystalline admixtures that block micro-capillaries in the concrete.

Plasticizers and superplasticizers to enhance density and reduce permeability.

These admixtures are mixed directly into the concrete during batching, offering internal water-blocking properties.

5.Applying External Waterproofing Membranes

Protecting the outside surface of underground tanks is critical in areas with high groundwater levels. Apply a flexible waterproofing membrane over the tank’s exterior.

Recommended Materials:

Bitumen-based coatings for cost-effective protection.

Polymer or rubberized sheet membranes for better elasticity and chemical resistance.

For added durability, apply multiple membrane layers with reinforcement mesh.

6.Using Post-Tensioning for Large or High-Load Tanks

For tanks exposed to heavy pressure or large volumes, post-tensioning provides enhanced resistance to cracking.

How It Works:

High-strength steel cables (tendons) are embedded into the concrete.

After curing, these cables are tensioned to compress the concrete structure, reducing tensile stress zones.

This is especially useful in commercial and industrial tanks.

7.Incorporating Control and Expansion Joints

Concrete expands and contracts due to temperature changes. Without joints, cracks may appear randomly.

Types of Joints:

Control joints guide shrinkage cracks to safe zones.

Expansion joints allow thermal movement in large tanks.

Seal these joints with flexible, water-tight sealants like polyurethane or silicone.

8.Thickening Critical Areas

Increasing the slab and wall thickness strengthens the tank against static and dynamic loads.

Slab Thickness: Thicker slabs reduce upward hydrostatic pressure from groundwater.

Wall Thickness: Supports lateral loads from stored water and soil pressure.

Edge Reinforcement: Focus on thickening at base-wall junctions and load transfer points.

9.Anchoring to Prevent Buoyancy Uplift

Underground tanks in high water table zones can become buoyant and shift or float without proper anchoring.

Solutions:

Deadman anchors made of heavy concrete blocks or piers.

Ground anchors fixed to the base slab.

Add mass to the foundation slab to balance upward pressure.

These steps keep the tank grounded during flooding or saturated conditions.

10.Proper Curing of Concrete

One of the most overlooked but critical steps is curing, which prevents premature drying, cracking, and strength loss.

Methods:

Maintain surface moisture using wet hessian cloths, plastic sheets, or sprinkling water for at least 10 days.

Apply curing compounds to retain internal moisture.

Proper curing improves compressive strength and reduces shrinkage-related cracks.

11.Sloped Base for Sediment Removal

A flat tank base allows sludge to accumulate and stagnate. Instead, design a sloped base that channels sediment toward a sump or drain outlet.

Provide 1–2% gradient toward the lowest point.

Reinforce this area since it bears the maximum sediment load.

This aids in routine maintenance and keeps water hygienic.

Summary Table: Key RCC Water Tank Reinforcement Strategies

| Reinforcement Method | Function |

|---|---|

| Steel Rebar Mesh | Provides core structural strength and crack resistance |

| Horizontal & Vertical Bars | Supports hoop stress and vertical loading |

| Shear Reinforcement | Protects against diagonal cracking |

| Waterproofing Additives | Enhances internal water resistance |

| External Membranes | Prevents groundwater ingress |

| Post-Tensioning | Increases tensile resistance in large tanks |

| Expansion & Control Joints | Mitigates cracking from temperature and shrinkage |

| Thicker Slabs and Walls | Adds compressive strength |

| Anchoring Systems | Prevents tank uplift in saturated ground |

| Proper Curing | Ensures long-term concrete integrity |

| Sloped Base Design | Facilitates easy cleaning and sludge removal |

Conclusion

Building a leak-proof and long-lasting RCC underground water tank requires more than just pouring concrete. From structural rebars and shear reinforcement to waterproofing techniques and anchoring systems, each step plays a vital role. Implementing these modern RCC tank reinforcement methods ensures your tank remains crack-free, corrosion-resistant, and resilient for decades—even in challenging soil and groundwater conditions.

Would you like a checklist, infographic, or PDF summary version for field use or client presentations?