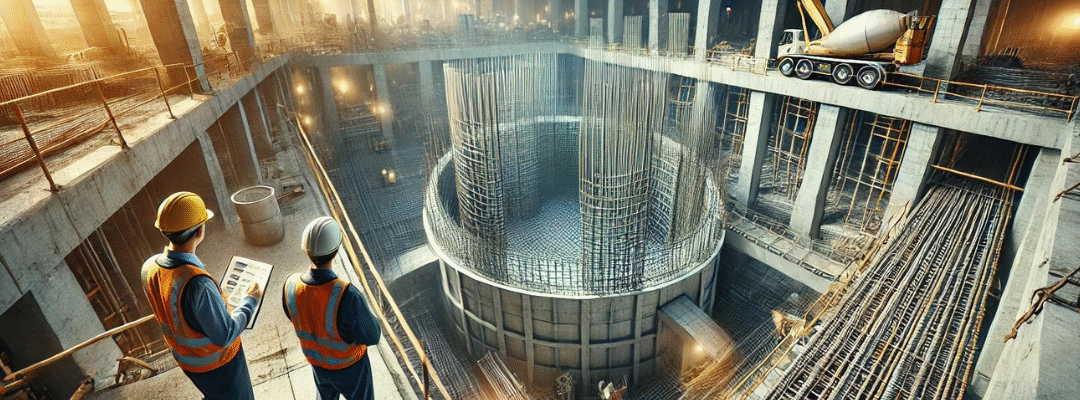

When constructing RCC (Reinforced Cement Concrete) underground water tanks, the choice of steel grade plays a pivotal role in ensuring structural strength, resilience, and long-term durability. Reinforcement bars (rebars) must bear tensile forces, resist corrosion, and prevent cracking under hydrostatic pressure and external soil loads. Selecting the right steel type is crucial for withstanding aggressive soil conditions, moisture exposure, and groundwater contact.

Common Steel Grades Used in RCC Water Tanks

Fe415 (Yield Strength: 415 MPa)

Overview: A widely used mild steel grade known for flexibility and reliability in conventional structures.

Ductility: Excellent flexibility under stress, especially in areas prone to minor soil movement.

Strength: Suitable for structures with moderate design loads.

Use Case: Ideal for small to medium-sized tanks in low-corrosion zones.

Benefits:

Economical for basic applications

Performs well in seismic zones due to energy-absorbing properties

Fe500 (Yield Strength: 500 MPa)

Overview: Stronger than Fe415, Fe500 offers enhanced load resistance and is suitable for high-performance RCC designs.

Balanced performance: Higher tensile strength with good ductility

Compatibility: Commonly available in TMT form with built-in corrosion resistance

Benefits:

Reduces overall steel volume in design

Ideal for larger tanks exposed to moderate soil and water pressure

Fe550 (Yield Strength: 550 MPa)

Overview: This grade provides superior mechanical performance for high-stress installations.

High strength: Withstands intense external loads and deeper installations

Durability: Resistant to fatigue, suitable for long-term use

Best For:

Large-capacity water tanks

Locations with heavy external pressures and harsh environmental conditions

Corrosion-Resistant Steel (CRS – Fe500D/Fe550D)

Overview: Engineered for environments with persistent moisture or aggressive soil chemistry.

High resistance to rust: Protective alloys minimize corrosion over time

Longer service life: Maintains integrity even under prolonged exposure

Applications:

Coastal areas, saline groundwater zones, and industrial setups

Advantages:

Reduced maintenance costs

Prolonged lifespan and lower lifecycle costs

Fe600 (Yield Strength: 600 MPa)

Overview: The most robust grade used in RCC tanks, designed for extreme structural demands.

Maximum strength: Handles very high tensile and compressive stresses

Lower ductility: Must be factored into design, especially in dynamic load zones

Applications:

Very large, deep underground tanks

Projects requiring maximum structural reliability with minimal steel quantity

Why Steel Grade Selection Matters in RCC Tank Design

Tensile Strength & Load Management

Stronger grades like Fe500/Fe550 help distribute load efficiently, reducing the risk of cracking due to internal water pressure and soil stress.

Corrosion Resistance

Tanks buried underground are constantly exposed to moisture and aggressive environments. CRS steel significantly improves resistance to rust and chemical degradation.

Ductility for Seismic Zones

Ductile grades (like Fe415 and Fe500) help the tank absorb movement without cracking—essential in earthquake-prone regions or areas with shifting soils.

Cost Optimization

High-strength grades enable thinner structural elements without sacrificing performance. This not only reduces steel quantity but also cuts down on long-term repair costs.

Standards & Compliance

Reinforcement must meet local codes such as IS 456:2000 to ensure structural soundness. Choosing a code-compliant grade ensures safety and legal conformity.

Compatibility with Concrete

Surface-roughened TMT bars (Fe500, Fe550) improve bond strength with concrete, while compatible thermal expansion behavior prevents cracking under temperature shifts.

Summary: Matching the Right Steel Grade with the Project

| Steel Grade | Strength (MPa) | Best For | Key Benefit |

|---|---|---|---|

| Fe415 | 415 | Small to mid tanks | Flexibility & affordability |

| Fe500 | 500 | Large tanks | Strong + ductile |

| Fe550 | 550 | High-pressure conditions | Durable & cost-saving |

| Fe500D/550D CRS | 500–550 | Corrosive soils | Rust protection |

| Fe600 | 600 | Max-load tanks | Highest strength |

Using the appropriate steel grade isn’t just a design choice—it’s a safeguard for long-term performance. From load resistance to corrosion prevention, your selection affects the tank’s lifespan, structural health, and maintenance requirements.

Whether you’re working in coastal regions, seismic zones, or industrial sites, choosing the right reinforcement steel ensures your RCC underground water tank performs safely and efficiently for decades.